News

Understanding the Role of Discharging Rollers in Industrial Processes

A discharging roller is a vital component in various industrial machinery, facilitating smooth and efficient material handling. This blog explores the functions, benefits, and applications of discharging rollers.

What Is a Discharging Roller?

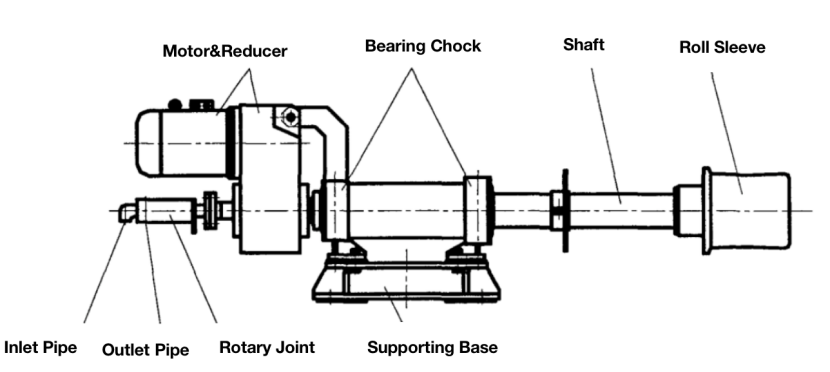

A Discharging roller is a cylindrical component used in conveyor systems, printing machines, and other industrial equipment. Its primary purpose is to move, guide, or discharge materials efficiently, ensuring seamless workflow in production lines.

Key Features of Discharging Rollers

-Durable Materials: Typically made from steel, rubber, or composite materials for longevity.-Precision Engineering: Ensures smooth rotation and alignment.

-Customizable Designs: Available in various sizes and surface finishes to suit specific applications.

Applications of Discharging Rollers

Discharging rollers are versatile and find applications across numerous industries. Here are some notable uses:Manufacturing and Assembly Lines

-Efficiently transfer materials between processes.

-Reduce manual labor by automating movement.

Printing and Packaging

-Ensure precise alignment of paper, films, or other materials.

-Assist in unloading finished products.

Material Handling Systems

-Used in conveyor belts to guide and discharge goods.

-Minimize friction and wear during transportation.

Benefits of Using Discharging Rollers

Investing in high-quality discharging rollers offers several advantages:-Improved Efficiency: Streamlines processes by automating material discharge.

-Cost Savings: Reduces wear and tear on machinery, lowering maintenance costs.

-Versatility: Suitable for a wide range of industrial applications.

Choosing the Right Discharging Roller

Selecting the right discharging roller for your application involves careful consideration of several factors:-Material Compatibility: Ensure the roller material matches the type of goods handled.

-Load Capacity: Opt for rollers designed to support the required weight.

-Surface Finish: Choose a texture that minimizes damage to materials.

Maintenance Tips for Discharging Rollers

To ensure the longevity and optimal performance of discharging rollers, follow these maintenance practices:-Regularly inspect for wear or damage.

-Clean the roller surface to prevent material buildup.

-Lubricate bearings as needed to ensure smooth operation.

Discharging rollers are indispensable in modern industrial setups, enabling efficient and seamless material handling. By understanding their functions and selecting the right type for specific applications, businesses can enhance productivity and reduce operational costs. Invest in quality discharging rollers to optimize your industrial processes and stay ahead in a competitive market.

.png?v=20250421)