News

Streamlining Efficiency: Everything You Need to Know About Discharging Rollers

Have you ever considered the unsung heroes of industrial operations? Discharging rollers play a pivotal role in various industries, ensuring seamless material movement and enhancing productivity. At Hotiongroup, we specialize in providing high-quality discharging rollers designed to meet diverse operational needs.

What is a Discharging Roller?

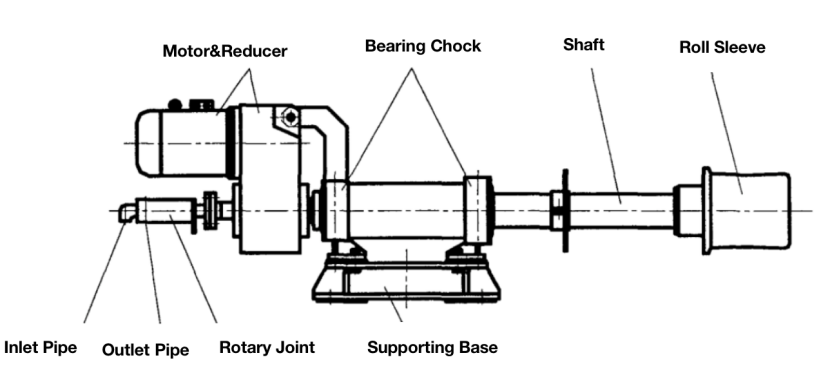

A Discharging Roller is an essential component used in conveyor systems to facilitate the smooth transfer of materials. These rollers are engineered to handle various loads and maintain optimal efficiency in industrial processes. Whether in manufacturing, packaging, or logistics, discharging rollers are indispensable for ensuring uninterrupted workflows.

Key Features of Discharging Rollers

1. High DurabilityConstructed from robust materials, discharging rollers are built to withstand heavy loads and harsh working conditions.

2. Smooth Material Handling

With precision engineering, these rollers ensure the seamless movement of goods, reducing friction and preventing damage.

3. Versatility

From lightweight to heavy-duty applications, discharging rollers cater to a wide range of industrial requirements.

4. Low Maintenance

Designed for longevity, discharging rollers require minimal maintenance, saving both time and costs.

Applications of Discharging Rollers

1. ManufacturingIn assembly lines, discharging rollers help in transferring components efficiently, boosting productivity.

2. Warehousing and Logistics

These rollers ensure quick and reliable material handling in storage and distribution centers.

3. Packaging

From boxed goods to bulk materials, discharging rollers simplify the packaging process by ensuring smooth movement.

4. Mining and Construction

In heavy industries, discharging rollers handle substantial loads, ensuring safety and efficiency.

Why Choose Hotiongroup for Discharging Rollers?

At Hotiongroup, we are committed to delivering top-notch solutions tailored to your needs. Here’s why our discharging rollers stand out:-Precision Engineering: Our rollers are crafted with cutting-edge technology for unparalleled performance.

-Durability: Built with high-grade materials, our rollers ensure long-lasting reliability.

-Custom Solutions: We offer tailored designs to meet specific industrial requirements.

FAQs About Discharging Rollers

1. What materials are used to make discharging rollers?

Discharging rollers are typically made from steel, aluminum, or other durable materials to ensure strength and longevity.2. Can discharging rollers handle heavy loads?

Yes, our discharging rollers are designed for both lightweight and heavy-duty applications.3. Are custom sizes available?

Absolutely! Hotiongroup provides customized roller designs to fit your operational needs.4. What industries benefit most from discharging rollers?

Manufacturing, logistics, packaging, mining, and construction industries rely heavily on these components.5. How do I maintain discharging rollers?

Regular cleaning and lubrication are sufficient to keep them functioning optimally.

Conclusion

Discharging rollers are vital for streamlining operations across various industries. At Hotiongroup, we take pride in offering durable, efficient, and customizable rollers that meet your specific requirements. Ready to upgrade your industrial processes? Contact Hotiongroup today to explore our range of discharging rollers and discover how we can enhance your operations!

.png?v=20250402)