News

How Does An Electromagnetic Stirrer Enhance Metal Processing

In the metal processing industry, achieving uniformity and consistency in molten metals is crucial. An electromagnetic stirrer is an innovative device that helps optimize the quality and properties of metals by providing efficient mixing.

The Functionality of an Electromagnetic Stirrer

An electromagnetic stirrer utilizes magnetic fields to create a stirring effect in molten metal without physical contact. This process offers several key benefits:- Homogeneous Mixing: Ensures even distribution of temperature and alloying elements.

- Improved Quality: Reduces defects and enhances the mechanical properties of the final product.

- Energy Efficiency: Minimizes energy consumption by optimizing heat transfer.

Advantages of Using an Electromagnetic Stirrer

Incorporating an electromagnetic stirrer in metal processing offers numerous advantages:- Contactless Operation: Prevents contamination and wear, increasing the lifespan of equipment.

- Precision Control: Allows for accurate adjustment of stirring intensity and direction.

- Enhanced Productivity: Speeds up the production process while maintaining quality.

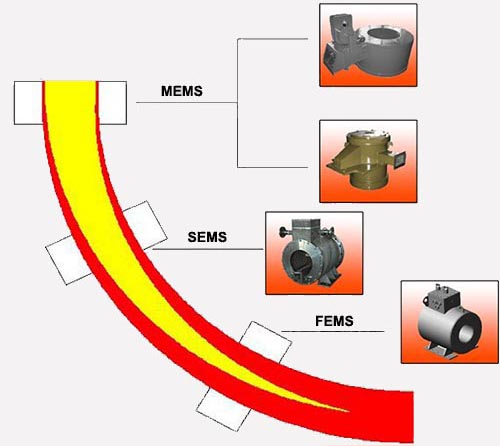

Applications of Electromagnetic Stirrer

Electromagnetic stirrers are used in various metal processing applications:- Steel Production: Ensures uniform composition and temperature distribution in molten steel.

- Aluminum Casting: Improves the quality of aluminum alloys by promoting even mixing.

- Foundries: Enhances the properties of non-ferrous metals and alloys.

Conclusion

The use of an electromagnetic stirrer in metal processing provides significant improvements in quality, efficiency, and productivity. By facilitating uniform mixing and precise control, it helps manufacturers produce high-quality metals and alloys with reduced energy consumption. As technology advances, the role of the electromagnetic stirrer will continue to grow, driving innovation in the metal processing industry.

.png?v=20250402)